feature / event / faculty / students / industrial-design / product-design / transportation-design

August 03, 2017

Writer: Solvej Schou

Photographer: Juan Posada

SNAP! ARTCENTER’S FORMULA-E RACE CAR COMPETITION USES RUBBER BANDS TO PROPEL TEAMWORK FORWARD

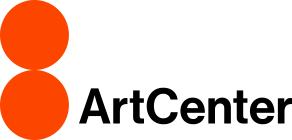

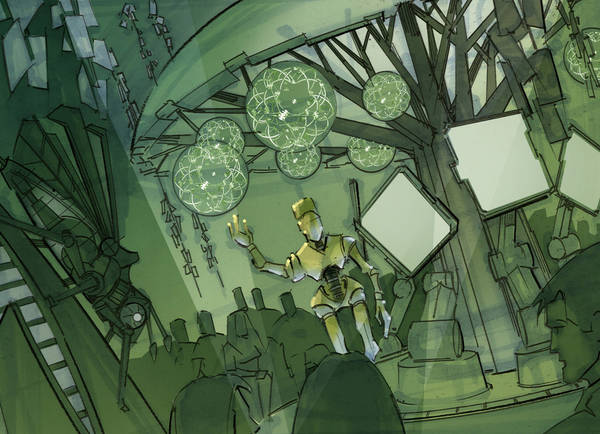

Imagine taking a 16-foot rubber band, stretching it taut and then twisting it and stuffing it into a carbon tube or another contraption—with wheels attached—created to look like a foot-long race car. When the wound-up rubber band is released, the car is off! Either to surge for 25 seconds with a burst of power down a track, or swerve and crash (but not burn).

ArtCenter’s annual international competition Formula-E—yes, the “E” is for “elastic”—will showcase on Thursday, August 10 both corporate and student teams who have worked towards just this purpose: win a 136-foot drag race course, a 322-foot figure eight course and a 228-foot hill climb using innovatively designed and constructed rubber-band powered race cars. The event takes place on the paved sidewalks of the Hillside Campus Sculpture Garden.

“This is a classic example of people doing something difficult together as a team that’s also a bonding and fun experience,” says Andy Ogden, who jumpstarted Formula-E in 2005 when he became ArtCenter’s Graduate Industrial Design chair.

This is a classic example of people doing something difficult together as a team that’s also a bonding and fun experience. Andy Ogden

This year, four teams of Graduate Industrial Design students and four teams of undergraduate Product Design and Transportation Design students, along with Pasadena City College students on each of those teams, will participate in the competition. Four Chinese teams who had won a June race in China—using a track that exactly replicates the Sculpture Garden’s sidewalks—are traveling to the final. Corporate participants include Honda and Mattel Hot Wheels.

“This is a very hard project, and people don’t realize how hard it is until they get into it,” says Ogden. “Design school education usually ends with a conceptual proposal. This actually has to work, and work within the constraints of a schedule.”

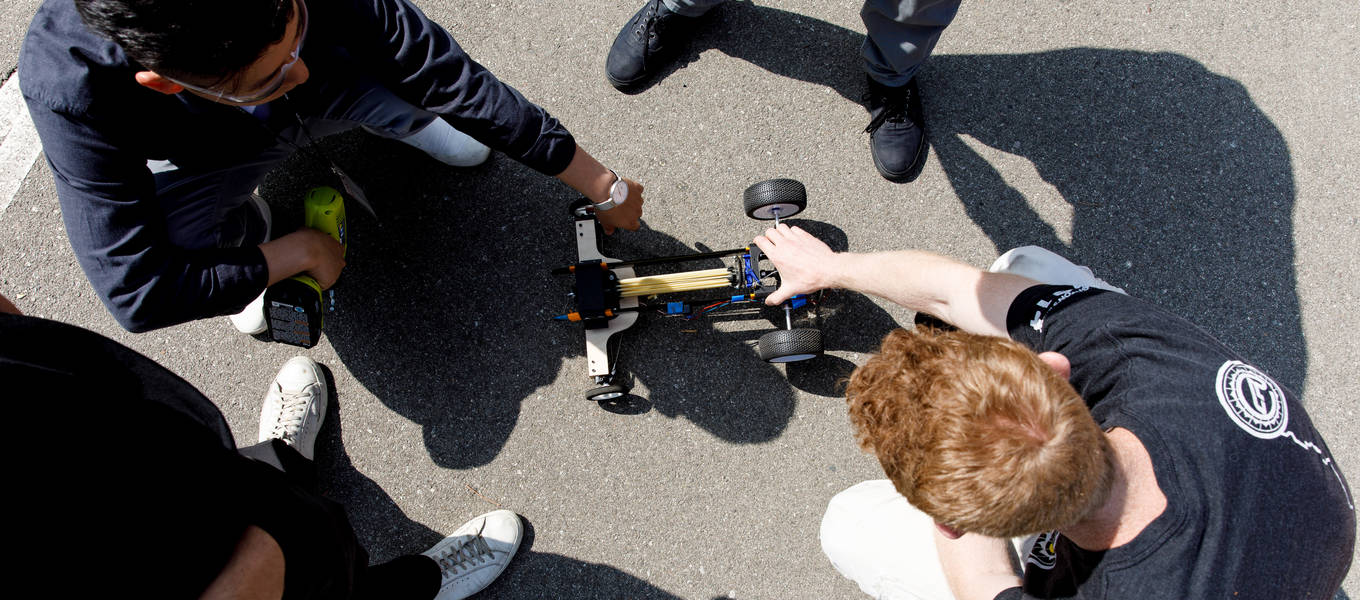

For the past 12 years, third term Graduate Industrial Design students have spent 13 weeks preparing for the race as part of their Summer 3D Development course. This term, for the first time, undergraduate Product Design and Transportation Design students have been able to take a Formula-E elective course. Formula-E’s ArtCenter roots, it turns out, go back to the ‘80s.

“The students I know who took the Formula-E course in the ‘80s and went on to be successful design professionals at Honda and Toyota would reminisce about it,” Ogden says.

Grad Industrial Design faculty Stan Kong, who along with co-instructor Javier Palomares takes students down the zig-zagging road of conceptualizing and constructing their race cars, cites Formula-E’s ability to stimulate “competition, comradery and working in teams to solve a problem that’s challenging.” Students start by reviewing different vehicles created in the past year, Kong says. Then they use 3D modeling software to design, calculate costs and foresee structural issues in advance, says Palomares. They make working models through a high-tech 3D printer, test them, narrow down an idea and build and refine many versions. Students “push all boundaries not only structurally but also aesthetically and performance-wise, always within budget,” says Palomares. Adds Ogden, “It’s a process of learning through testing and failure.”

As for ArtCenter’s Formula-E gaining steam in China—Chinese teams have won final races in past years—Ogden celebrates the competition’s global appeal. “Chinese schools participating signifies the importance of relationships we’ve cultivated with Chinese ArtCenter graduates and with Chinese companies,” he says. “We welcome schools and companies all over the world to enter.”